About

Inertia bases are used to support mechanical equipment, reduce equipment vibration, provide for attachment of vibration isolators, prevent differential movement between driving and driven members, reduce rocking by lowering equipment center of gravity, reduce motion of equipment during start-up and shut-down, act to reduce reaction movement due to operating loads on equipment, and act as a noise barrier.

Inertia bases vary from a simple steel frame which allows spring mounts to connect to the equipment through to large concrete filled frames to provide inertial mass. We can engineer an inertia base’s frame to suit project requirements in terms of size, mass and finish. Typical uses for inertia base frames, with poured concrete and supported by noise and vibration isolators, include use with open-type centrifugal chillers, reciprocating air and refrigeration compressors, chillers, and heat pumps, close-coupled and base-mounted pumps, centrifugal fans, internal combustion engines, and similar types of equipment.

Frames incorporate a unique structural design which integrates perimeter channels, isolator support brackets, reinforcing rods, anchor bolts and concrete fill into a controlled load transfer system, utilizing steel in tension and concrete in compression, resulting in high strength and stiffness with minimum steel frame weight. Completed inertia bases using model TFT CIB frames are stronger and stiffer than standard inertia base frames using heavier steel member.

Bases are delivered to job site completely welded and ready to fill with concrete. On-job labour and installation time are minimized, resulting in maximum economy.

Types of Inertia Bases

TFT CIB – L

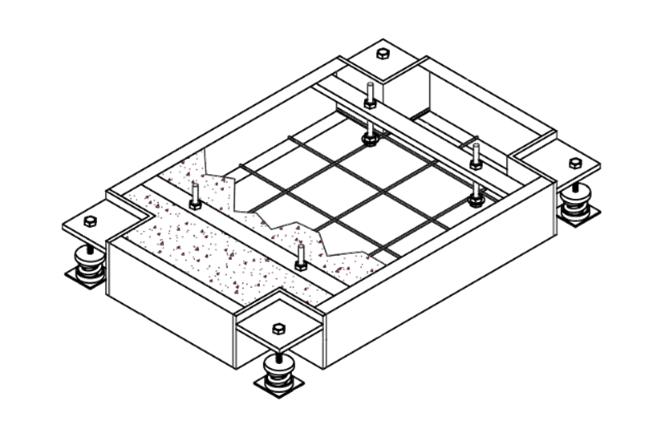

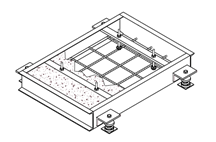

Model TFT CIB-L inertia base frames, when filled with concrete, meet all specifications for inertia bases, and when supported by proper vibration isolators, provide the ultimate in equipment isolation, support, anchorage, and vibration amplitude control. TFT CIB-L inertia base frames incorporate a unique design which integrates formed perimeter channels, isolator support brackets, reinforcing rods, anchor bolts and concrete fill into a controlled load transfer system, utilizing steel in tension and concrete in compression, resulting in high strength and stiffness with minimum steel frame weight. Completed inertia bases using model TFT CIB-L frames are stronger and stiffer than standard inertia base frames using heavier steel members.

Standard TFT CIB-L Inertia Base frames are available in thicknesses of 150 mm, 200 mm, 250 mm and 300 mm, in sizes tabulated, and include integral isolator support brackets, steel channel perimeter pouring frame, 12 mm diameter rebar on nominal 200 mm centers each way, and steel anchor bolts prelocated and fixed in proper locations. TFT CIB-L inertia base frames are delivered to the job site completely welded and ready to fill with concrete.

Isolation bases shall be constructed of concrete cast into fabricated inertia base frames, the steel members of which are designed and supplied by the isolator manufacturer. The concrete shall be poured into a welded steel frame, incorporating prelocated equipment anchor bolts, 12 mm diameter rebar on nominal 200 mm centers each way, and recessed isolator mounting brackets to reduce the mounting height of the equipment, and reduce the footprint of the base. The thickness of the base shall be a minimum of 10% of the longest span between isolators, at least 150 mm, or as indicated on the drawings. Where inertia bases are used to mount pumps, the bases shall be sized to support piping elbows.

TFT CIB – H

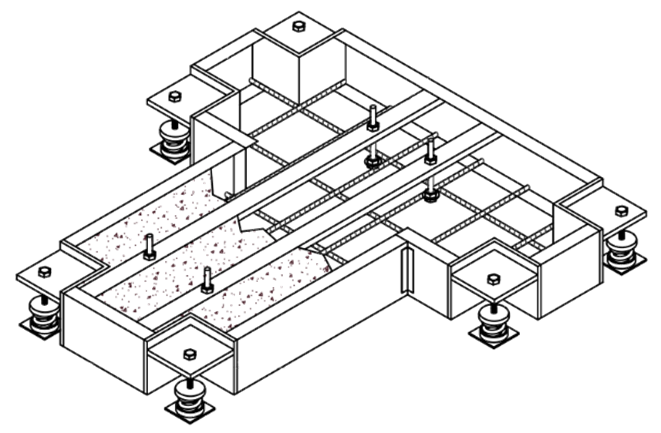

TFT CIB-H inertia base frames, when filled with concrete and supported by proper noise and vibration isolators, provide outstanding equipment isolation, support, anchorage, and vibration amplitude control.

TFT CIB-H inertia base frames incorporate welded structural steel channel perimeter frames of sizes and depths specified. Also included are steel isolator brackets, welded-in steel reinforcing rods, and equipment anchor bolts, if required.

Model TFT CIB-H inertia base frames minimize installation time and job site labor by arriving at the job site completely assembled and ready to fill with concrete. Isolation bases shall be constructed of concrete cast into fabricated inertia base frames, the steel members of which are designed and supplied by the isolator manufacturer. The concrete shall be poured into a welded structural steel frame, which incorporates prelocated equipment anchor bolts (optional), 12 mm diameter reinforcing bars on nominal 200 mm centers each way, and external isolator mounting brackets to reduce the mounting height of the equipment.The thickness of the base shall be a minimum of 10% of the longest span between isolators, at least 150 mm, or as indicated on the drawings. Where inertia bases are used to mount pumps, the bases shall be sized to support piping elbows.

TFT CIB – F